The

Roper Solar Greenhouse

Roper Solar Greenhouse215 Maywood Street, Blacksburg, Virginia

Located in the Hale-YMCA Community Gardens

Roper Solar Greenhouse

Roper Solar GreenhouseRegularly redisplay this web page to keep up on the progress of the YMCA Solar Greenhouse.

Back to the main YMCA Solar Greenhouse web page

Operation Data

Inside Construction

Building a SGH with SHCS

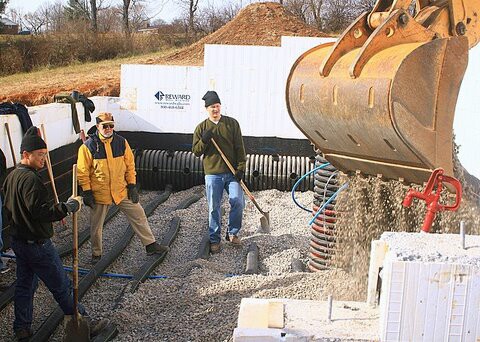

Excavation by J. W. B. Contractors (23 October 2008): |

|

ICF (Insulated Concrete Forms; made from recycled materials): |

|

Expanded polystyrene held together by strong polypropylene ties 6" apart. The ties are connected to plastic furring strips for attaching finishes on both sides. |

|

|

Preparing to install the ICF:  |

Installing the ICF under guidance of Doug Hoback:  Dave Roper is "supervising". |

ICF is in place!:  |

Jeff Ligon & Conrock & Green Valley Builders pouring the concrete into the ICF (18 November 2008, 27°F day) : |

|

Justin Boyle inspecting. |

|

|

|

|

Ready to build the heat sink:  |

|

Starting to put in the 3' of rocks:  |

Putting rocks over the first layer of 4" slotted pipes:  Note that the wiring and plumbing has been installed in the rocks. |

Putting rocks over the 3rd (last) layer of 4" slotted pipes:  |

Heat sink is finished!: The water tank will be on the north side of the center-post pillar. The waterproofing of the walls needs to be higher. The pipe at the center of the west wall is the input pipe, on which the fan will be installed. The longer pipe will go on top of it with a screen on its top to keep animals out. |

The two outlet pipes with the elbows will direct air over the plants:  There will be screens over the outlets to keep animals out. |

|

One of the rafters is bowed, but not enough to cause a problem:  |

Installing the top beam.  |

John Sullivan, Jason Boyle and Justin Boyle installing the top beam and rafters:  |

South roof rafters and blocking boards in place for installing polycarbonate: The 2nd-from-the-right rafter was the bowed one. Hammer Down Construction managed to take out most of the bow when inserting the purlins. Note that the center post has been installed. |

West wall ready for Hardie board:  |

East wall ready for Hardie board:  |

Installing the polycarbonate; Pat Bixler up high:  Richard Reid and Justin Boyle handing the first sheet. |

Richard Reid and Dave Roper installing the first sheet:  Pat Bixler "supervising". |

Almost half done installing the polycarbonate:  |

Jason Boyle on top putting on the last sheet. Chris Roberts behind him. Justin Boyle and Tim Colley below:

|

Chris Roberts on the "Poly Slide" installing the final screws.  Pat Bixler and Jason Boyle assisting: |

A day of happiness (14 Feb 2009):  |

|

|

Volunteers Laura Doody cleaning up & Tyler Nichols filling cracks. |

Steven DiStefano Siding Company crew installing Hardie siding inside & outside:  |

West inside view with Hardie board installed:  |

East inside view with Hardie board and door installed:  |

Slanting Hardie board at bottom of polycarbonate inside:  |

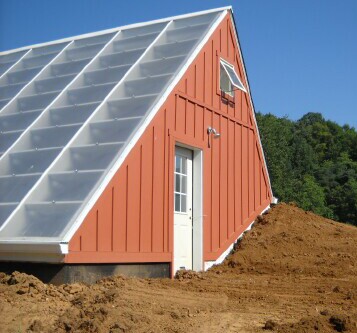

East side done except for painting and landscaping:  |

West side done except for painting and landscaping:  |

Sarah Vosti of the Chi Delta Alpha service sorority painting up high:  |

Caron Sinnerberg of the Chi Delta Alpha service sorority picking up trash:  |

Kelly Daly of the Chi Delta Alpha service sorority painting the roof:  |

Two primer coats in place:  |

|

Chris Roberts and Pat Bixler installing the electical cabinets inside and outside:  |

|

Roof finished by Henderson Roofing:  |

Debbie Wiley starting putting soil inside:  |

Hardie-board boundary between the rocks under the walkway and the soil:  |

Debbie Wiley after putting soil inside:  |

Walkway rocks in place:  Berek Crawford did much of it. |

Walkway done: |

Abigail Convery painting up high:  |

2000-gallons cistern in place:  It was designed as a septic tank and made by CT Jamison Precast. |

Cistern pipes:  |

Backfill mostly done:  |

Dave Roper after painting the ends with Dave Nickerson:  |

Inlet pipe in place above the heat-sink fan:  |

Concrete pad is ready for the water tank:  |

Steven DiStefano Siding Company put the ridge cap on:  |

Heat-sink fan wired and shelves built around the heat-sink inlet pipe:

|

Access to the cistern:  |

Pipes and wiring to cistern:  It includes a float switch to turn off sump pump when water level is low. |

Cistern cover:  |

Exhaust fan installed:  |

Water system installed:  |

Gutters installed:  |

Bug screens on the downspouts and cistern overflow pipe:  |

| |  |

Backfill:  |

|

|

Screen door installed (10 August 2009):  |

Patio construction by Heritage Stone Productions  |

K-Guard Gutters

|

|

Patio walls construction by Heritage Stone Productions (8 September 2010):  |

Back to the main YMCA Solar Greenhouse web page

L. David Roper, http://www.roperld.com/personal/roperldavid.htm; roperld@vt.edu

06-Apr-2016