L. David Roper

http://www.roperld.com/personal/roperldavid.htm

6 April, 2016

Biodiesel appears to be the ideal fuel for transportation after electricity:

There is a web page devoted to studies about producing biodiesel from algae.

Why make biodiesel from algae?:

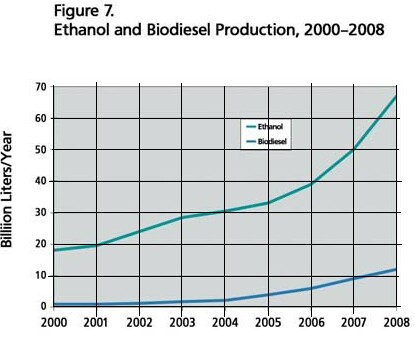

Ethanol has dominated biodiesel as a biofuel:

This is because of the prominece of corn (U.S.) and sugar cane (Brazil) as food crops, which have been greatly diverted to biofuel production. As a result the price of food has skyrocketed. There is a movement away from corn to other sources as a foodstock for ethanol; algae may be one of those sources.

Biodiesel has a higher energy content (~34.5x106 J/liter = 9.58 kWh/liter) than ethanol (~22x106 J/Liter = 6.1 kWh/liter).

I believe that eventually biodiesel will pass ethanol as the dominant biofuel.

Diesel vehicles made in Germany in 2006 achieved high mpg, and competed with gasoline engines with regard to emissions. The much lower emissions of hybrids make them more desirable than diesel vehicles. Also, better driving performance can be engineered into hybrid vehicles than for a comparable-emissions conventional gasoline or diesel vehicle.

There is another form of diesel made from plants: biodiesel (http://en.wikipedia.org/wiki/Biodiesel). It is a mixture of long-chain esters. Biodiesel can be used as fuel for diesel vehicles without any engine alteration or it can be mixed with petroleum-diesel. (The usual mixture is B20: 20% biodiesel.) It is slightly less efficient than diesel, but more efficient than gasoline. It produces much less vehicle emissions than diesel. Most biodiesel is made from plants that are planted and harvested by burning gasoline or diesel in farm tractors and with fertilizer, all made from petroleum; this needs to be changed drastically so that biodiesel production is carbon neutral. (http://www.unh.edu/p2/biodiesel/media/NHSTA05.ppt)

Biodiesel can be used in heating buildings in place of petroleum fuel oil. In fact, biodiesel will clean the combustion crud out of an old furnace. (It takes some time after starting to burn biodiesel in an old furnace, changing the fuel filter often, to clean out all of the crud.)

A major problem with using biodiesel as a vehicle fuel is that it gels at temperatures below about 4 °C (40 °F). Blending biodiesel with petro-diesel can alleviate the problem. For plug-in hybrid vehicles, it should be possible to use a small amount of battery energy to prevent gelling. The gelling temperature is different depending on what plant is used to make biodiesel. Additives can reduce the gelling temperature.

We can look forward to biodiesel hybrid vehicles in the future when more efficient biofueled and bio-fertilized farming methods are used to produce biodiesel.

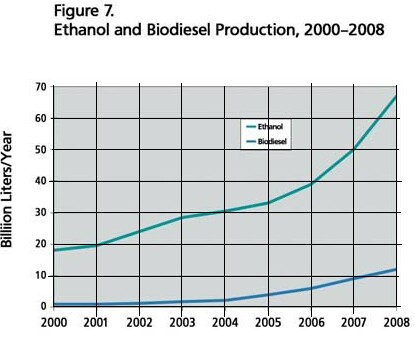

Probably the best renewable fuel for the future is biodiesel. For the reasons see Pahl (Pahl, 2008). Using data taken from Renewables: Global Status Report, the graph below shows the biodiesel-production history data for the world, most of which has been in Western Europe, and a mathematical fit to the data to use for projection into the future.

TWh = 1012 Wh = 109 kWh.

I did not use the 2008 point in the fit because it is out of line of the long-term trend, probably due to the deep recession. The hyperbolic-tangent function is used in the fit; see below for more details about the fit.

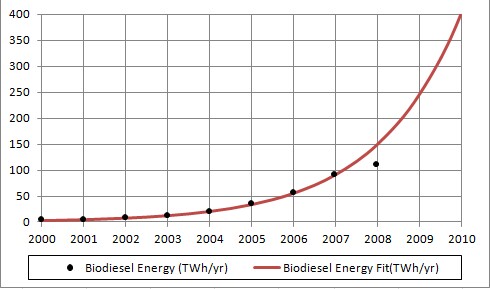

The dominant renewable fuel for vehicles has been ethanol in the United States using corn as the feedstock and in Brazil using sugar cane as the feedstock, because corn and sugar cane are major crops for those two countries. Many govenment incentives have helped to push ethanol forward.

Using data taken from Renewables: Global Status Report, the graph below shows the ethanol-production history data for the world, most of which has been in Western Europe, and a mathematical fit to the data to use for projection into the future.

I did not use the 2008 point in the fit because it is out of line of the long-term trend, probably due to the huge government subsidies. The hyperbolic-tangent function is used in the fit; see below for more details about the fit.

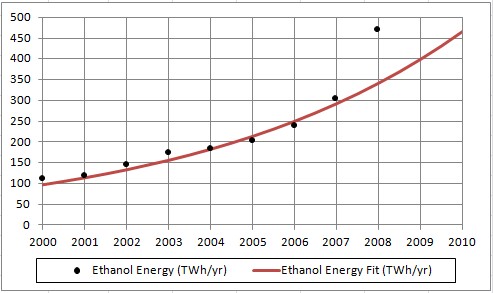

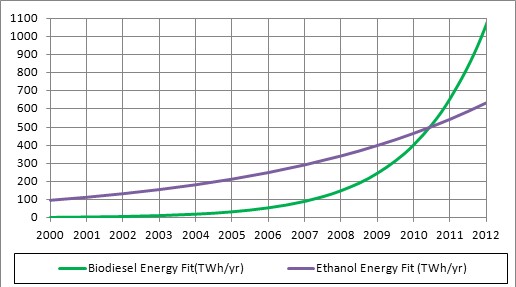

The mathematical fits to the biodiesel and ethanol data allows projection into the future. Since biodiesel production is growing faster than ethanol production, there is a crossover time around the middle of 2010:

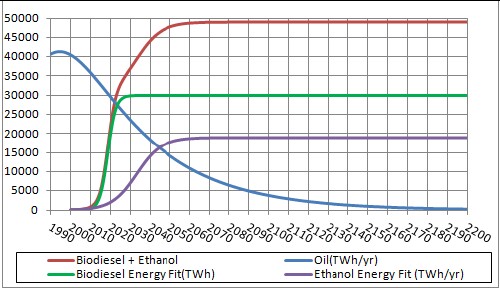

The following graph compares the future projections of biodiesel production and ethanol projection with the World crude oil extraction projection.

For the assumptions used in fitting biofuels production, biofuels energy exceeds the energy available from crude-oil extraction before 2025.

The assumptions used to achieve the biodiesel and ethanol asymptotes are:

The hyperbolic parameters are:

| Biodiesel | Ethanol | |

Asymptote (TWh) |

30000 |

19000 |

Break Point Year |

2019 |

2033 |

Width (years) |

4.0 |

12.6 |

The biodiesel rise rate is about three times faster than the ethanol rise rate. The asymptotic liters produced is about 3x1012 for both biodiesel and ethanol.

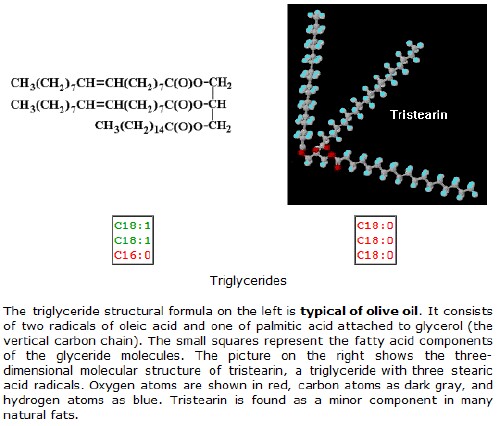

Food preparation uses massive amounts of vegetable oil, such as olive oil and canola (rapeseed) oil. Most modern diesel engines cannot burn used vegetable oil without damaging the engine (Pahl, 2008). However, used vegeatable oil can be converted to biodiesel.

http://www.scientificpsychic.com/fitness/fattyacids1.html:

(Tristearin is in palm oil and is produced in processing beef and cod-liver oil.)

Canola Oil made from rapeseed: C3H5O6C(CnH(2n+x))3 where, n = 15, 17, 19 or 21 x= plus or minus 1. -3, or -5.

One of the most promising crops for producing biodiesel is algae. Calculations show that, because of the high concentration of oil (over 50%) in some algae species, enough biodiesel to replace petroleum for transportation fuel can be grown on a few percent of the farm land in the United States. Marginal farm land, such as desert land, works just fine. It can be grown as seaweed in coastal waters. (http://en.wikipedia.org/wiki/Seaweed) Perhaps algae farming in desert countries would be a way to improve living standards there. Algae can grow in almost any water environment.

Another plant, mustard, can be grown to provide biodiesel feed stock, alcohol feedstock for the 10% alcohol needed to process biodiesel, and organic pesticides.

Some alcohol (ethanol or methanol ) is required to produce biodiesel from vegetable oils and animal oils :

10 parts of natural oil + 1 part of alcohol -> 10 parts biodiesel + 1 part glycerin. The glycerin is sold as a byproduct.

There are some algae that produce ethanol as part of their normal living process. Algenol Biofuels is working on commercializing this process. http://en.wikipedia.org/wiki/Algenol : "Algenol claim the process can produce 6,000 US gallons per acre per year (5,600 m3/km2·a) as compared with around 370 US gallons per acre per year (350 m3/km2·a) produced by growing corn and fermenting it and 890 US gallons per acre per year (830 m3/km2·a) for sugar cane. The algae is grown in salt water and so can be grown in desert areas using sea water rather than needing existing agricultural land and water sources. Their process also uses carbon dioxide generally obtained as a waste product from power stations."

Earth land area: 1.49x108 km2 (29%). Surface area: 5.10x108 km2. (1 km2=247.1 acres=100 hectares). Arable land: 13.31% of surface (6.8x107 km2); 4.71% (2.4x107 km2) supports permanent crops. 40% is used for cropland and pasture (1.3x107 km2 cropland, 3.4x107 pastureland). Mean height of land above sea level is 840 m.

World Renewable Energy

L. David Roper Interdisplinary Studies