Grasscrete Parking Lot

L. David Roper

http://www.roperld.com/personal/InterdisciplinaryStudies.htm

6 April, 2016

Back to Roper Energy Apartments

After extensive study, the owner decided that Grasscrete may be a good option for making the driveway part of the east parking lot pervious to water. See details about installing a Grasscrete parking lot for REA.

Layout

- Parking spaces: pervious concrete

- Drive lane between parking spaces: 5.5” Grasscrete mesh-reinforced concrete with sandy topsoil, with polyacrylamide water retention additive, in voids; grass planted in topsoil. (Grass is not planted on top of the concrete portions of Grasscrete since snow plowing occurs during winters.)

Base

- All areas should be leveled to 5.5” below final grade after base additions.

- Top of base is 1” of resin-bonded sand to make it easy to level the Grasscrete molded-pulp Former.

- In accordance with local concrete street specifications. (E.g., soil with minimum R value of 30 and compaction of 95%; poor soil should be removed down at least 4” and replaced with compacted #57 stone (1/2”-3/2”) topped by 1” resin-bonded sand.) (Minimum ground bearing of 45 kN/m 2 = 45 kPa = 0.45 millibar = 6.5 psi) (If cohesive clay, underlying large-stone drainage blanket surrounded by geotextile.)

- Typically 6” of #57 stone with 95% compaction, topped by 1” resin-bonded sand is adequate base.

- Soil R Value

The molded-pulp Former is made of 100% recycled paper that is biodegradable:

Staging boards are used for walking on the formers while installing the concrete. (See pictures below.) "The concrete is cast slightly higher than the Former tops to allow for a clean void to be opened either later the same day or early the next dependent upon conditions. The final surface is broom finished..." The Former tops are punched down into the voids after the concrete has hardened.

Nearest Grasscrete Contractor to Blacksburg VA

CAROLINA BOMANITE CORP., 4933 Chastain Ave., Charlotte, NC 28217, 704-364-1854; FAX: 704-527-7789, www.carolinabomanite.com, john@carolinabomanite.com

Go to top

Grasscrete-Formers References

- Minimum compressive strength of 3000 psi in 28 days

- Portland Cement: ASTMC 150, Type I, II or V

- Aggregates: ASTM C 33 with 3/8” maximum size

- Can have ~45% fly ash with 100% reclaimed crushed concrete aggregate.

- Can use fiber reinforcement.

- Welded wire mesh: 6” x 6” and 10 gauge x 10 gauge, chaired 2”-3” above base

- Expansion joints (1/2” impregnated fiberboard) at 30’ intervals with 4” trowelled margins to both sides of expansion joints

- Use staging board on which to pour concrete and smooth to top of plastic forms with rubber squeegee. Do not tamp concrete. The final surface is brush finished.

- Minimum 4” finished-concrete margins at parking-lot edges

- Do not tamp concrete.

- Grasscrete Suggested Mix Designs

Grasscrete References

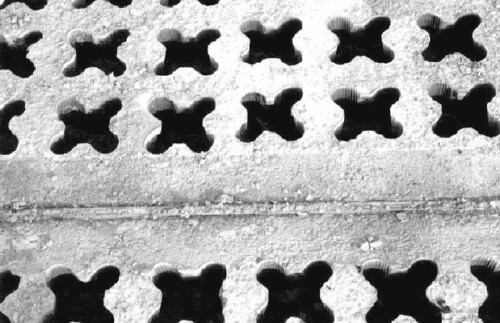

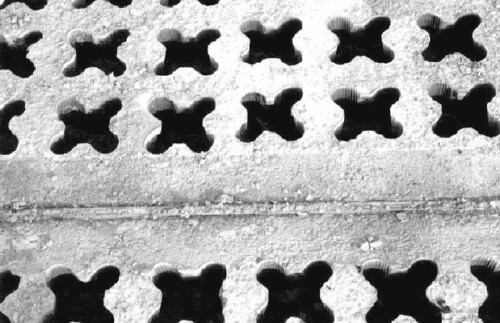

Grasscrete Pictures

Pouring concrete for Grasscrete using staging board:  |

Grasscrete expansion joint:  |

Tamping Down Grasscrete Former tops:  |